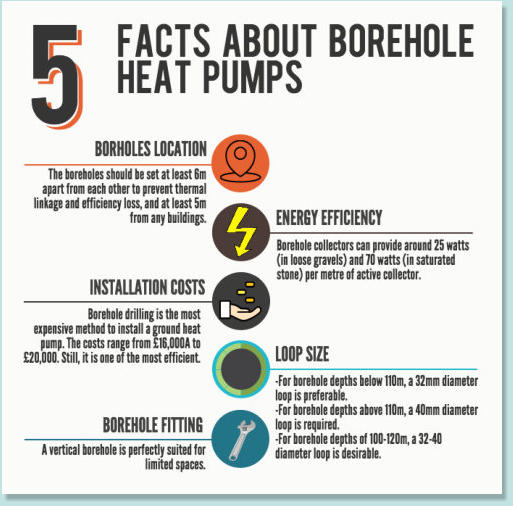

Vertical boreholes are good for small or limited areas, and although it bears high installation costs, borehole heat collectors

produce a higher heat yield per metre, compared to horizontal collectors, which entails a better energy efficiency rate. Thus, if

you are considering drilling a borehole in your backyard, you’ll have to make sure that the ground is suitable for digging a

deep-seated ditch and that the designated area is accessible for fitting in the drilling equipment.

What is a Ground Source Heat Pump Borehole?

A borehole type heat pump represents a closed loop system which comprises a

set of polyethylene pipes that are vertically inserted into the ground and which

circulate water to and from the geothermal heat pump. In most cases, the

borehole size will range between 15m and 122 m (50-400 feet) deep.

The space between the pipes and the borehole wall is filled up with a special

grout mix that typically contains a combination of bentonite, sand and potable

water, which is being pumped from bottom to top. Bentonite is preferable to

other grouting materials, since it is waterproof and a good thermal conductor.

Therefore, by retaining a considerable amount of moisture it rarely dries out

which ensures a proper heat transfer from the ground to the pipe and vice versa.

At the same time, due to its low permeability properties, the bentonite grout

provides a self-sealing barrier to groundwater intrusion. The boreholes are

drilled at 5-6 m apart from each other and at 6-7 m from the nearest building.

The depth is conditional on the property’s characteristics (size, insulation,

heating capacity) that requires heating. A house that needs around 10 kW of

heating capacity, most probably will need three boreholes of 80 to 110 m deep.

Borehole Collectors Installation and Operational Costs

The costs associated with a borehole heat pump installation are directly proportional on such factors as borehole depth,

borehole casing and sealing materials dimensions. In order to make sure that you will make the most out of the boreholes you

are planning to drill, you can order a geotechnical survey to be carried out beforehand.

In so doing, you’ll be able to minimise the degree of uncertainty when it comes to the soil’s thermal properties assessment and

it will make sure that the heating capacity you are looking to obtain by installing a ground source heat pump will pay off the

initial investment. At the same time, a survey like this will provide a reliable amount of data that will be instrumental in planning

the right length and diameter of the borehole loop, that will correspond with the ground’s characteristics.

The smaller the system, the higher the cost per kW output will be. As mentioned earlier, for all the types of ground source heat

pumps that use a borehole as their main heat source collector, the setting up costs (planning, equipment utilisation and the

commission of works) are a substantial part of the total costs. Thus, the capital cost measured in pounds per borehole meter

that is being drilled, will decrease as the collector size increases.

This means that, for a group of ten houses which are located on the same site, the borehole collector costs per house will be

around 20% lower than for an individual house. Meanwhile, the overall costs of the heat pump that determines its’ output in

terms of pounds per kW, will drop as well, provided that the heat pump output gets larger.

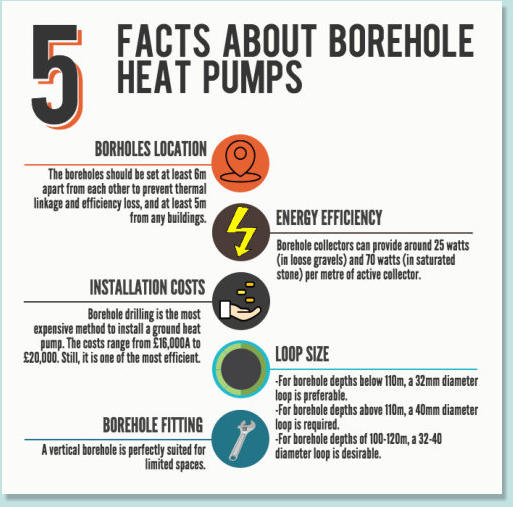

Vertical boreholes are good for small or limited areas, and although it bears high installation costs,

borehole heat collectors produce a higher heat yield per metre, compared to horizontal collectors,

which entails a better energy efficiency rate. Thus, if you are considering drilling a borehole in your

backyard, you’ll have to make sure that the ground is suitable for digging a deep-seated ditch and

that the designated area is accessible for fitting in the drilling equipment.

What is a Ground Source Heat Pump Borehole?

A borehole type heat pump represents a closed

loop system which comprises a set of

polyethylene pipes that are vertically inserted

into the ground and which circulate water to

and from the geothermal heat pump. In most

cases, the borehole size will range between

15m and 122 m (50-400 feet) deep.

The space between the pipes and the borehole

wall is filled up with a special grout mix that

typically contains a combination of bentonite,

sand and potable water, which is being pumped

from bottom to top. Bentonite is preferable to

other grouting materials, since it is waterproof

and a good thermal conductor. Therefore, by

retaining a considerable amount of moisture it

rarely dries out which ensures a proper heat

transfer from the ground to the pipe and vice

versa. At the same time, due to its low permeability properties, the bentonite grout provides a self-

sealing barrier to groundwater intrusion. The boreholes are drilled at 5-6 m apart from each other

and at 6-7 m from the nearest building. The depth is conditional on the property’s characteristics

(size, insulation, heating capacity) that requires heating. A house that needs around 10 kW of

heating capacity, most probably will need three boreholes of 80 to 110 m deep.

Borehole Collectors Installation and Operational Costs

The costs associated with a borehole heat pump installation are directly proportional on such

factors as borehole depth, borehole casing and sealing materials dimensions. In order to make

sure that you will make the most out of the boreholes you are planning to drill, you can order a

geotechnical survey to be carried out beforehand.

In so doing, you’ll be able to minimise the degree of uncertainty when it comes to the soil’s thermal

properties assessment and it will make sure that the heating capacity you are looking to obtain by

installing a ground source heat pump will pay off the initial investment. At the same time, a survey

like this will provide a reliable amount of data that will be instrumental in planning the right length

and diameter of the borehole loop, that will correspond with the ground’s characteristics.

The smaller the system, the higher the cost per kW output will be. As mentioned earlier, for all the

types of ground source heat pumps that use a borehole as their main heat source collector, the

setting up costs (planning, equipment utilisation and the commission of works) are a substantial

part of the total costs. Thus, the capital cost measured in pounds per borehole meter that is being

drilled, will decrease as the collector size increases.

This means that, for a group of ten houses which are located on the same site, the borehole

collector costs per house will be around 20% lower than for an individual house. Meanwhile, the

overall costs of the heat pump that determines its’ output in terms of pounds per kW, will drop as

well, provided that the heat pump output gets larger.

Biomass Installer Yorkshire

Balcas Brites

Biomass Pellet Supplier

Biomass Boilers Yorkshire

Biomass Boilers

Biomass Yorkshire

MCS

AECB

Biomass Lancashire

Biomass Heating Yorkshire

Biomass Heating

Solar Heating

Biomass Boilers

Solar PV

Biomass heat Yorkshire

Fit Tarriffs

ASHP Yorkshire

ASHP Lancashire

GSHP Yorkshire

ASHP Lancashire

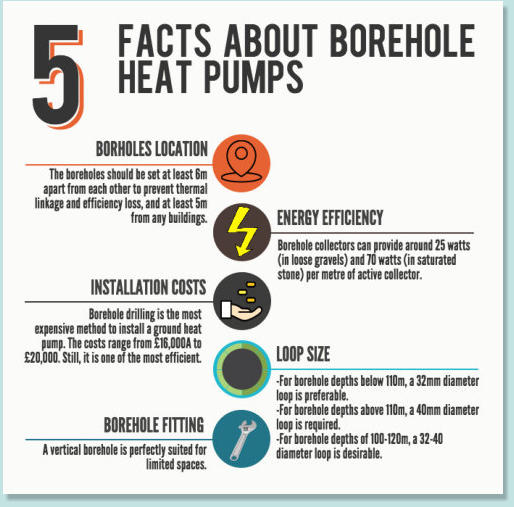

Vertical boreholes are good for small or limited areas, and

although it bears high installation costs, borehole heat

collectors produce a higher heat yield per metre,

compared to horizontal collectors, which entails a better

energy efficiency rate. Thus, if you are considering drilling

a borehole in your backyard, you’ll have to make sure that

the ground is suitable for digging a deep-seated ditch and

that the designated area is accessible for fitting in the

drilling equipment.

What is a Ground Source Heat Pump Borehole?

A borehole type heat pump represents a closed loop

system which comprises a set of polyethylene pipes that

are vertically inserted into the ground and which circulate

water to and from the geothermal heat pump. In most

cases, the borehole size will range between 15m and 122

m (50-400 feet) deep.

The space between the pipes and the borehole wall is

filled up with a special grout mix that typically contains a

combination of bentonite, sand and potable water, which

is being pumped from bottom to top. Bentonite is

preferable to other grouting materials, since it is

waterproof and a good thermal conductor. Therefore, by

retaining a considerable amount of moisture it rarely dries

out which ensures a proper heat transfer from the ground

to the pipe and vice versa. At the same time, due to its

low permeability properties, the bentonite grout provides a

self-sealing barrier to groundwater intrusion. The

boreholes are drilled at 5-6 m apart from each other and

at 6-7 m from the nearest building. The depth is

conditional on the property’s characteristics (size,

insulation, heating capacity) that requires heating. A

house that needs around 10 kW of heating capacity, most

probably will need three boreholes of 80 to 110 m deep.

Borehole Collectors Installation and Operational Costs

The costs associated with a borehole heat pump

installation are directly proportional on such factors as

borehole depth, borehole casing and sealing materials

dimensions. In order to make sure that you will make the

most out of the boreholes you are planning to drill, you

can order a geotechnical survey to be carried out

beforehand.

In so doing, you’ll be able to minimise the degree of

uncertainty when it comes to the soil’s thermal properties

assessment and it will make sure that the heating

capacity you are looking to obtain by installing a ground

source heat pump will pay off the initial investment. At the

same time, a survey like this will provide a reliable

amount of data that will be instrumental in planning the

right length and diameter of the borehole loop, that will

correspond with the ground’s characteristics.

The smaller the system, the higher the cost per kW output

will be. As mentioned earlier, for all the types of ground

source heat pumps that use a borehole as their main heat

source collector, the setting up costs (planning,

equipment utilisation and the commission of works) are a

substantial part of the total costs. Thus, the capital cost

measured in pounds per borehole meter that is being

drilled, will decrease as the collector size increases.

This means that, for a group of ten houses which are

located on the same site, the borehole collector costs per

house will be around 20% lower than for an individual

house. Meanwhile, the overall costs of the heat pump that

determines its’ output in terms of pounds per kW, will drop

as well, provided that the heat pump output gets larger.

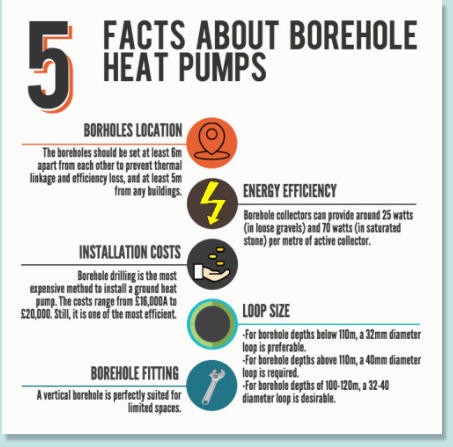

Vertical boreholes are good for small or

limited areas, and although it bears high

installation costs, borehole heat collectors

produce a higher heat yield per metre,

compared to horizontal collectors, which

entails a better energy efficiency rate. Thus, if

you are considering drilling a borehole in your

backyard, you’ll have to make sure that the

ground is suitable for digging a deep-seated

ditch and that the designated area is

accessible for fitting in the drilling equipment.

What is a Ground Source Heat Pump

Borehole?

A borehole type heat pump represents a

closed loop system which comprises a set of

polyethylene pipes that are vertically inserted

into the ground and which circulate water to

and from the geothermal heat pump. In most

cases, the borehole size will range between

15m and 122 m (50-400 feet) deep.

The space between the pipes and the

borehole wall is filled up with a special grout

mix that typically contains a combination of

bentonite, sand and potable water, which is

being pumped from bottom to top. Bentonite is

preferable to other grouting materials, since it

is waterproof and a good thermal conductor.

Therefore, by retaining a considerable amount

of moisture it rarely dries out which ensures a

proper heat transfer from the ground to the

pipe and vice versa. At the same time, due to

its low permeability properties, the bentonite

grout provides a self-sealing barrier to

groundwater intrusion. The boreholes are

drilled at 5-6 m apart from each other and at

6-7 m from the nearest building. The depth is

conditional on the property’s characteristics

(size, insulation, heating capacity) that

requires heating. A house that needs around

10 kW of heating capacity, most probably will

need three boreholes of 80 to 110 m deep.

Borehole Collectors Installation and

Operational Costs

The costs associated with a borehole heat

pump installation are directly proportional on

such factors as borehole depth, borehole

casing and sealing materials dimensions. In

order to make sure that you will make the

most out of the boreholes you are planning to

drill, you can order a geotechnical survey to

be carried out beforehand.

In so doing, you’ll be able to minimise the

degree of uncertainty when it comes to the

soil’s thermal properties assessment and it

will make sure that the heating capacity you

are looking to obtain by installing a ground

source heat pump will pay off the initial

investment. At the same time, a survey like

this will provide a reliable amount of data that

will be instrumental in planning the right length

and diameter of the borehole loop, that will

correspond with the ground’s characteristics.

The smaller the system, the higher the cost

per kW output will be. As mentioned earlier,

for all the types of ground source heat pumps

that use a borehole as their main heat source

collector, the setting up costs (planning,

equipment utilisation and the commission of

works) are a substantial part of the total costs.

Thus, the capital cost measured in pounds per

borehole meter that is being drilled, will

decrease as the collector size increases.

This means that, for a group of ten houses

which are located on the same site, the

borehole collector costs per house will be

around 20% lower than for an individual

house. Meanwhile, the overall costs of the

heat pump that determines its’ output in terms

of pounds per kW, will drop as well, provided

that the heat pump output gets larger.

Tel: 01282 786900 Mob: 07790 215 065

© 2016 Reliable Renewables Ltd.

GSHP Boreholes

Tel: 01282 786900 Mob: 07790 215 065

© 2016 Reliable Renewables Ltd.

GSHP Boreholes

07790 215 065

© Copyright Reliable Renewables Ltd 2016

Tel:

01282 786900

Mob:

GSHP Boreholes

© Copyright Reliable Renewables Ltd 2016

Tel:

01282 786900

Mob:

07790 215 065

GSHP Boreholes